Call: 07971189837

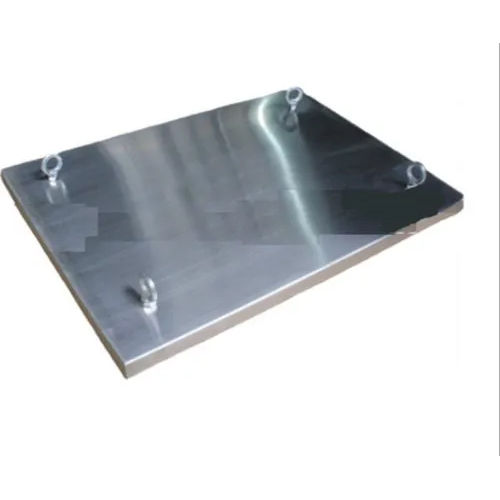

Plate Type Magnetic Separator

Price 7130 INR/ Piece

MOQ : 1 Piece

Plate Type Magnetic Separator Specification

- Magnet Grade

- N52 or higher

- Thickness

- 8-15 mm

- Magnet Category

- Permanent Magnet

- Machine Type

- Magnetic Separator

- Composite

- Single Layer/Double Layer (customizable)

- Shape

- Rectangular Plate

- Application

- Separation of ferrous contaminants from granular and powder material

- Size

- 300 mm x 300 mm (standard/customizable)

- Weight

- 12-18 kg (varies with size)

- Color

- Metallic Silver

- Function

- Removal of iron impurities

- Capacity

- Customize as per requirement

- Brand Required

- Optional/As per requirement

- Material

- Stainless Steel (SS304/SS316)

Plate Type Magnetic Separator Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 3 Months

- Main Domestic Market

- All India

About Plate Type Magnetic Separator

Access unparalleled performance and separation efficiency with our Plate Type Magnetic Separator, featuring a stellar polished stainless steel finish and corrosion-resistant design. Get instant removal of ferrous contaminants from granular or powder materials in food, chemical, mining, ceramic, and pharmaceutical industries. Engineered for crowning reliability, this magnetic separator delivers up to 10 years of operating life, with uncommon customization options in size, mounting, and capacity. With powerful neodymium magnets (N52+), it provides a magnetic intensity of 4000-10,000 Gauss and supports installation over chutes, ducts, or conveyors-putting clean, pure output within your reach.

Versatile Applications and Advanced Features

The Plate Type Magnetic Separator excels in a range of industries-food processing, chemical, mining, ceramics, plastics, and recycling. Apply it in chutes, ducts, or over conveyors for direct separation of iron impurities from powders or granules. Its uncommon features include customizable sizes, shapes, grades, and mounting methods. Constructed from polished SS304/SS316 with single or double layers, this separator ensures both durability and easy manual cleaning, making it a crowning asset in protection and purity maintenance.

Payment Terms, Certifications, and Supply Capacity

Rapid fulfillment and robust supply ability enable continuous access to this magnetic separator. Standard packaging ensures safety during transit, and outlay is determined by the list price and customization. Certified for quality and efficiency, we cater to contracts of varying sizes. Flexible payment terms are available, accommodating both bulk and small-scale orders. Manufactured in India, our product's packaging and certifications reflect our focus on international standards and client satisfaction worldwide.

Versatile Applications and Advanced Features

The Plate Type Magnetic Separator excels in a range of industries-food processing, chemical, mining, ceramics, plastics, and recycling. Apply it in chutes, ducts, or over conveyors for direct separation of iron impurities from powders or granules. Its uncommon features include customizable sizes, shapes, grades, and mounting methods. Constructed from polished SS304/SS316 with single or double layers, this separator ensures both durability and easy manual cleaning, making it a crowning asset in protection and purity maintenance.

Payment Terms, Certifications, and Supply Capacity

Rapid fulfillment and robust supply ability enable continuous access to this magnetic separator. Standard packaging ensures safety during transit, and outlay is determined by the list price and customization. Certified for quality and efficiency, we cater to contracts of varying sizes. Flexible payment terms are available, accommodating both bulk and small-scale orders. Manufactured in India, our product's packaging and certifications reflect our focus on international standards and client satisfaction worldwide.

| Capacity | 0.5 Ton/Hour |

| Type Of Magnet Used | Neodymium |

| Type Of Plate Magnet | Standard Magnetic Plates |

| Applications | Food Processing Industry, Recycling And Waste Processing |

| Gauss Value | 4000 Gauss |

| Country Of Origin | Made In India |

FAQ's of Plate Type Magnetic Separator:

Q: How does the Plate Type Magnetic Separator ensure ferrous contaminant removal?

A: The separator uses high-intensity permanent neodymium magnets (up to 10,000 Gauss) to effectively attract and capture iron impurities, providing clean, contaminant-free material output.Q: What industries benefit most from using this magnetic separator?

A: Industries such as food, chemicals, pharmaceuticals, mining, ceramic, and plastic processing get stellar benefits from implementing this separator, as it enhances product purity and protects processing equipment.Q: Where can this magnetic separator be installed?

A: Its versatile design allows installation in chutes, ducts, and over conveyors, adapting to various industrial layouts and material flows.Q: What is the process for cleaning the Plate Type Magnetic Separator?

A: The separator features a manual cleaning method, letting operators easily remove trapped iron contaminants for continued efficient operation.Q: When should the separator be serviced or inspected?

A: Routine inspection and cleaning according to usage level is advised, but with standard conditions, the separator can function reliably for over 10 years before needing significant maintenance.Q: What are the outlay and packaging options for this separator?

A: The outlay depends on the list price, selected features, and customization. We provide secure, export-grade packaging tailored to your outlay and shipping requirements.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Magnetic Separator Category

Neodymium Pot Magnet

Price 100 INR / Piece

Minimum Order Quantity : 1 Piece

Function : Provides strong magnetic force for industrial and technical applications

Brand Required : Optional; Compatible with multiple brands

Material : Neodymium (NdFeB), Steel Pot Casing

Thickness : 5 mm to 30 mm (varies by model)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry