Call: 07971189837

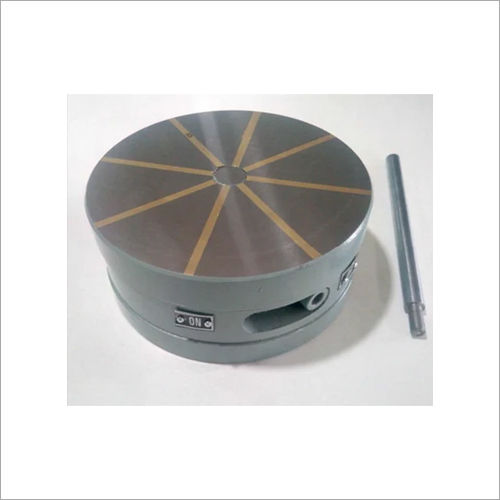

Electromagnetic Round Chuck

Price 19000 INR/ Piece

MOQ : 5 Pieces

Electromagnetic Round Chuck Specification

- Thickness

- 60 mm to 100 mm

- Magnet Category

- Electromagnetic

- Magnet Grade

- Industrial Grade

- Machine Type

- Surface Grinder, Lathe, Milling

- Composite

- Steel & Brass Top Plate

- Shape

- Round

- Application

- Grinding, Milling, Turning, Surface Finishing

- Size

- 150 mm to 600 mm Diameter

- Weight

- 10 kg to 120 kg (depending on size)

- Color

- Black & Metallic Silver

- Function

- Powerful magnetic holding for round workpieces

- Brand Required

- Customizable / As Required

- Capacity

- Upto 1000 kg

- Material

- High Grade Steel, Brass (Pole Cover)

Electromagnetic Round Chuck Trade Information

- Minimum Order Quantity

- 5 Pieces

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 2000 Pieces Per Week

- Delivery Time

- 3 - 6 Days

- Main Domestic Market

- All India

About Electromagnetic Round Chuck

Electromagnetic Round Chuck are modern devices replacing vices mechanical clamps and fixtures For clamping and unclamping of the machined components electromagnetic electro permanent and permanent magnetic chucks are used This allows the workpiece to be accessible from five 5 sides and does not damage the product The magnetic force of Electromagnetic Round Chuck can be as strong as up to 16kg cm2 and will not deteriorate with time

Advanced Magnetic Holding for Versatile Machining

This Electromagnetic Round Chuck provides powerful, adjustable magnetic holding for a variety of machining tasks. Its industrial-grade build, premium steel and brass construction, and IP54+ protection ensure durability and longevity in challenging environments. Ideal for applications in grinding, milling, turning, and finishing, it supports customizable sizes, capacities, and mounting options, making it a flexible choice for professionals looking to optimize workflow on round workpieces.

Precision, Safety, and Efficiency Combined

With a meticulously finished top plate, superior surface flatness, and oil-proof construction, this round chuck enhances machining accuracy while safeguarding equipment. The remote ON/OFF control and robust insulation resistance contribute to safe, efficient operation, while adaptable mounting fixes and customizable cable length fit a wide range of workshop setups. Its high magnet grade guarantees solid workpiece retention even under heavy loads up to 1000 kg.

FAQ's of Electromagnetic Round Chuck:

Q: How does the Electromagnetic Round Chuck improve workflow for grinding or milling round workpieces?

A: The chuck offers a powerful magnetic holding force and fine pole options, ensuring the secure retention of round workpieces during machining. Its quick remote ON/OFF switching streamlines setup and changeovers, minimizing downtime and enhancing precision in operations like grinding, milling, and turning.Q: What mounting options are available for installing the round chuck on my machine?

A: You can choose either a center bore or side tappings, depending on your machine's requirements. This flexibility allows easy adaptation for various setups, supporting machines like surface grinders, lathes, and milling centers.Q: When should I select the standard vs. fine pole pitch option?

A: The standard pole pitch (12-20 mm) is ideal for larger workpieces or general machining, while the fine option is better suited for smaller, thin components requiring improved magnetic distribution and holding accuracy during intricate finishing tasks.Q: Where can I use this round chuck, and what environments is it suitable for?

A: This chuck is designed for professional workshops and manufacturing facilities handling grinding, milling, turning, or finishing of round components. Oil and coolant-proof construction with IP54 or higher protection makes it suitable for harsh industrial settings across India.Q: What process does the remote ON/OFF switch facilitate in daily usage?

A: The remote ON/OFF switch allows effortless activation and deactivation of the magnetic field, simplifying the setup and release of workpieces. This aids in maintaining workflow efficiency and boosts operational safety by reducing manual intervention.Q: What are the benefits of custom cable length and brand selection options?

A: Customizable cable length ensures easy integration into various workspaces, while the option to specify a preferred brand allows alignment with existing equipment standards or procurement policies, supporting optimized and personalized use.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry